Basic overview

Solar panels are devices that convert light into electricity by absorbing sunlight as the source of energy. They consist of a connected assembly of solar cells that can come in different sizes and electrical specifications, and are able to produce voltage and current. The solar cell is considered the basic building block of all solar panels that starts out from silicon and becomes a semiconductor that acts as both an electrical conductor and insulator when exposed to sunlight. The solar cells are doped during manufacturing, usually by other elements such as boron and phosphorous, to become semiconductors and allow for the flow of electrons.

We have different types of PV modules and can be referred to as two main types of crystalline modules. These two types of modules include the type with monocrystalline cells and polycrystalline cells. Monocrystalline solar panels are generally more efficient than the polycrystalline solar panels due to the uniform molecular structure within the monocrystalline cell that allows for the movement of a greater amount of electrons when under sunlight since the cells are better lined up and facing the same direction. In contrast, the polycrystalline solar panels have cells with crystal structures of various shapes that face different directions, which ends up somewhat reducing the panel efficiency.

Solar panels are rated at different voltage, current and wattage values. Our panel products come with labels on the backsheet with different electrical specification values from the manufacturer. The two current values that are reported on the solar panel label specs are Isc and Imp. Isc refers to short-circuit current, which is the current value if the positive and negative solar panel wires come into contact with no resistance. These values are reported on the label at standard test conditions (STC). Imp refers to maximum power current, or optimum operating current, which is the current value when the panel is producing the max amount of power and when the solar panel is operating in a system. The two voltage values that are reported on the solar panel specs are Voc and Vmp. Voc refers to open circuit voltage, which is the voltage value when you check the voltage of a panel using a multimeter on the disconnected positive and negative panel wires. Vmp refers to maximum power voltage, or optimum operating voltage, which is the voltage when the solar panel is operating in a system.

Another important spec value to consider in the solar panel labels is the irradiance value, which is the measure of solar power as the rate of solar energy power onto the area of a solar panel surface. It is usually measured as W/m^2.

Nameplate

Test condition(STC): This is how much power the panel is rated at the Standard Test Condition, which is 1000 W/m2.

Peak Circuit Voltage(Voc): This is the panel’s voltage level when it is not hooked up to a controller and battery. It is important when sizing systems with controllers as panels will have this value for a short period of time when the system is hooked up. Also, this is important when troubleshooting a solar panel.

Max Power Voltage(Vmp): This is the voltage level of the panel when it is set up and operating. This is important for calculating wire gauge size and wire length.

Max Power Current(Imp): This is the current being produced when the panel is set up and operating. This is important for calculating wire gauge size, wire length, and controller sizing.

Short Circuit Current (Isc): This is the panel’s voltage level when it is not hooked up to a controller and battery. This is important when troubleshooting a solar panel.

Solar Panels in the basic sense work by converting available sunlight into usable electricity. The way we define this power is by watts. Watts are made up of amps and volts. Different panels have different ratings for amps and volts, and it is helpful to understand what these numbers mean when you are looking at a system. You can imagine amps as the amount of electrons, and the voltage the amount of pressure pushing those electrons.

Equation: Watts = Volts x Amps

COMPONENTS

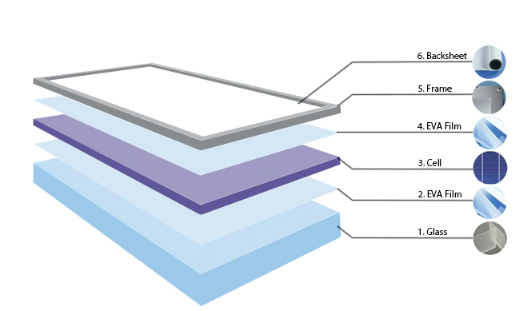

A solar panel is made up of different components as seen in Model 2.1.1. Not all panels will have these specific components in the specific locations, but generally our panels have this.

Solar Cell (2.1.1.6): The solar cells can be seen on front of the solar panel. They vary in color and appearance based depending on the type of cell. The type of cell generally defines what kind of panel it is, for example monocrystalline, polycrystalline, amorphous, etc.

Frame (2.1.1.5): MostACOPOWER Solar panels have an aluminum frame, but depending on the type of panel frame type can vary.

Junction Box (2.1.1.1): The junction box is generally located on the back of the panel. It contains bypass diodes to help with power loss due to shading. Also it serves as a connection and a holder for the panel wires.

Wire (2.1.1.3): Our ACOPOWER solar panels come with standard PV wire that is weatherproof and insulated (as long as there is no exposed copper wire).

MC4 (2.1.1.4): At the end of the PV wire is a MC4 connector. This MC4 connector is standard in the PV industry, is weatherproof and serves as a connection point to our other MC4 cable, such as an adaptor kit.

Specification Sheet (2.1.1.2): The panel’s specification sheet will tell you the electrical characteristics of your solar panel. It is very important when sizing systems.

MONOCRYSTALLINE VS. POLYCRYSTALLINE

Monocrystalline solar panels are slightly higher in efficiency than polycrystalline panels because each utilizes a different manufacturing technique. A monocrystalline cell consists of a single crystal ingot, whereas a polycrystalline cell consists of a growth containing multiple crystal structures. Both types of cells are made from silicon ingots, but the purity requirement of the silicon is higher on a monocrystalline base. Therefore, monocrystalline panels are more efficient, and thus, more expensive. By using a single cell, monocrystalline based silicon allows the electron greater freedom to move, so less energy is lost and higher efficiency is created. Most monocrystalline cells peak at 22% efficiency, whereas most polycrystalline cells peak at 18% efficiency. Monocrystalline cells are a dark blue almost appearing black, and polycrystalline cells are blue.

Even though this is true, there is a common misconception that monocrystalline solar panels will actually perform better than polycrystalline panels even in situations where they have the same wattage. This is not true. A 100W Mono Panel should perform just as well as a 100W Poly Panel, assuming the electrical characteristics are very close. A customer’s decision should be based on the price, the dimensions, and the color. Also due to common misconception, Poly and Mono panels should perform the same under low light conditions. They also should perform the same under high temperatures.

SOLAR PEAK HOURS AND IRRADIANCE

It is important to use the peak hours with the wattage of your system to calculate how many watt hours your system produces in a day. You can view peak sun hours as an average, as basing power off the hours of daylight during the day isn’t sufficient. The reason why is because sunlight in the morning and evening will not produce as much radiation as solar during midday. To calculate each states peak hours, the radiation is averaged based on the highs and lows and also other factors such as what is mixed into the atmosphere.

As you can see from the data gathered Model 2.1.2, the level of irradiance or W/m2 varies throughout the day. The panels output is directly related to the W/m2 at that given time. Most solar panels are rated at 1000 W/m2. If the irradiance level is let’s say 500 W/m2, like it is at 8am in the graph, then you should expect half the output (50%). Because of this fact, the solar peak hours of your state isn’t how long the sun it out, but an average from the lows and the highs so that it can be a reliable number in calculating energy generation.